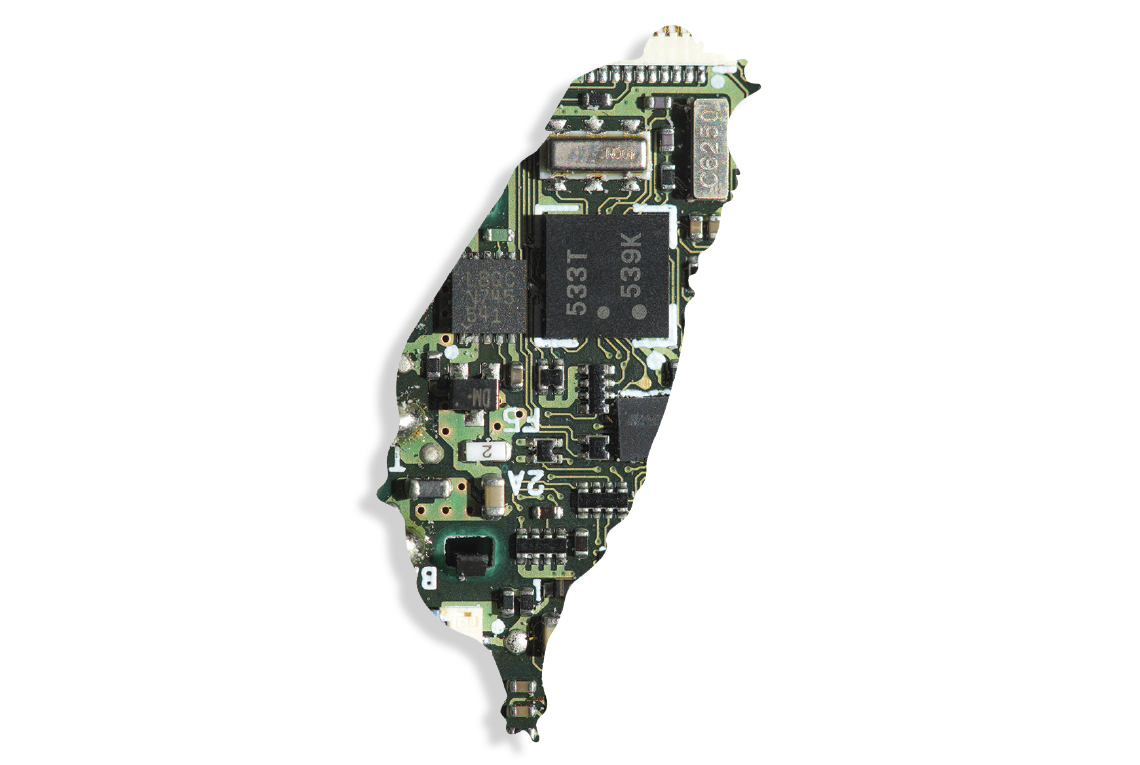

TSMC: The Biggest Winner in Taiwan’s Exceptional Response to COVID-19

535 cases and 7 deaths (Worldometer, 2020). After 9 months of the pandemic, how did a country with 23 million people and such a close proximity to the COVID-19 outbreak manage to have so much success in fending off the virus? Moreover, how did Taiwan’s robust response to the pandemic help further monopolize Taiwan Semiconductor (TSMC), the industry leader in global semiconductor manufacturing? Our story doesn’t begin in January, when Taiwan started implementing travel restrictions and mandatory health screenings prior to entering the country. It actually begins in 2003, with the SARS outbreak. After 668 cases, 181 deaths, and over 130,000 quarantined, Taiwan began preparations for the next outbreak by founding the National Health Command Center (NHCC) (Hsieh et al., 2004; Chen et al., 2005). The NHCC was established to stop another pandemic before it could enter Taiwan (Wang, 2020). By establishing a central system to combat outbreaks, Taiwan established stringent protocols years in advance, resulting in an exceptional response to the current COVID-19 pandemic.

The efficacy of Taiwan’s response to the pandemic is likely attributable to culture. Generally, Taiwanese people are very willing to give up some individual freedoms for the betterment of the overall community, but in the US, many would rather prioritize the individual over the community. This is most prevalent in these countries’ responses to COVID-19. While in the US, people were fighting over masks and hoarding toilet paper, the Taiwanese government stepped in and instituted rationing of all personal protective equipment (PPE) supplies (Farr, 2020). Additionally, Taiwan immediately ramped up production of masks to accommodate increasing demand. The stark cultural difference between Taiwan’s collectivism and America’s individualism has also created a substantive difference in the two countries attitudes’ toward wearing a mask. Since the SARS outbreak in 2003, wearing masks in public places has been common for the Taiwanese. This is vastly different from the US, where the mere suggestion of mandatory mask wearing led to immediate pushback on the grounds of violating individual rights.

Moreover, Taiwan was better equipped to handle COVID-19 compared to the US because of its centralized health care system. Within weeks of the WHO informing the world of the strange new strand of coronavirus in Wuhan, Taiwan had already established quarantine wards and easy access testing for people suspected of having COVID-19, and most public and private establishments had temperature checking and mandatory mask wearing (Farr, 2020). These rules were all generally followed, as there were strict fines and societal pressures to comply, including publicly releasing people’s names who were not following quarantine or mask mandates. Also, in Taiwan’s governmentally-operated healthcare system, all of an individual’s records are tied to their name, which allowed for the rapid alert to doctors if they had patients at risk.

After the pandemic worsened in March, Taiwan started to lock down the island. Only citizens were allowed into Taiwan, and, upon arrival, were subject to rigorous tracking through a mobile device along with a mandatory 14-day quarantine in a hotel (Lee, 2020). Even to this day, almost no non-citizens are allowed to travel to Taiwan, and all are still required to follow all guidelines mentioned above. All of these restrictions and regulations, while seemingly pointless back in 2004, have seemed to pay off in 2020, with Taiwan being the only country with no continuous increases in domestic cases (Wang and Ellis, 2020).

So, how did an adept response from Taiwan’s government and willingness to cooperate from the citizens allow an already industry-leading company to further dominate?

Taiwan Semiconductor (TSMC), which was founded in 1987 as the first dedicated semiconductor foundry, meaning that they don’t design their own chips, but rather produce other companies’ designs. Today, TSMC is one of two companies able to produce and deliver the smallest chips in terms of nanometers (5nm), and are years ahead on R&D for 3nm and 2nm chips, with the 3nm ready for production in 2022, and 2nm being announced as “ahead of schedule” earlier this year (Chen and Shen, 2020; Owen, 2020). Since 2014, TSMC has dominated over 50% of the market share by maintaining around 500 clients, including some of the biggest tech companies in the world: Apple, AMD, Qualcomm, Nvidia (Sun, 2020).

With Taiwan having effectively eliminated COVID-19, life has returned to pre-COVID conditions. Students are going to school, Restaurants are open, and businesses are operating, meaning that TSMC has been able to keep its manufacturing churning. While its foreign competitors struggled due to their respective countries mishandling of the pandemic, TSMC has been able to capitalize on the shortcomings of other market players during the pandemic. Taiwan Semiconductor’s success has seemingly hinged on the deft response by both the government and the communities of Taiwan.

The first catalyst of growth in both the business and stock price of TSMC has been Apple, as they are the largest customer of TSMC, accounting for 23% of the company’s revenue (Sun, 2020). In May, it was announced that Apple would be setting up an R&D plant in TSMC’s Hsinchu Science Park (Taipei Times, 2020). This meant that Apple was starting to shift even more of its business to TSMC and away from Samsung, a direct competitor of TSMC, benefiting the core of TSMC’s business. Apple’s distancing from TSMC competitors continued in June, when Apple announced they were shifting away from Intel processors and starting to design their own silicon chips (Apple, 2020). Apple actually does not produce their own chips, so this announcement caused a small boost in TSMC stock as they would be presumptive producers of the new Apple silicon chips (Owen, 2020). Again, this was a direct shift of Apple’s business from a direct competitor of TSMC (Intel) to TSMC. In fact, Apple has already also announced that they would be exclusively sending all of the 5nm orders they needed to TSMC, booking the entire production capacity of TSMC’s 5nm chips in 2020 (Sohail, 2019; Hruska, 2020). The A14 and A14X chips, produced with TSMC 5nm technology, will be used in all of Apple’s new devices in 2020, including the iPhone 12, iPad Air, and Apple Watch Series 6 (Hruska, 2020).

However, the largest catalyst to TSMC’s growth actually occured in July, when Intel announced that they had to delay their 7nm chip due to production problems (Fox, 2020). This had a large impact on TSMC’s business because now that Intel couldn’t deliver on their products, other companies in the chip design industry could start to take advantage. Again, this benefited TSMC, as they are the producer of chips for most of Intel’s competitors, notably AMD (Sun, 2020). Back in September, AMD shifted even more product orders of 7nm chips to TSMC, meaning that all of the increased demand due to Intel’s lack of production would go to TSMC (McKellop, 2020). Intel’s problem also meant they needed to outsource their production to other manufacturers to not fall behind, and you guessed it: they went straight to TSMC (Mahaney, 2020). These consequences of Intel’s announcement caused a huge boost to TSMC’s share price, from $67 to $83 within two days of the announcement, a 62% increase (Yahoo! Finance, 2020).

Since then, the stock has held steady, with another small jump caused by the announcement of the Apple Keynote on October 13th. In anticipation of the Keynote, investors began pricing in the iPhone 12 and the 5G technology that represent the next generation of mobile technology. Around 47% of TSMC’s top line last year was due to smartphone chips; Apple’s announcement of their Keynote caused the share price to approach $91 a share, up 30% in the last 3 months and up over 78% over the last year (Yahoo! Finance, 2020).

Overall, an already dominant player in the semiconductor industry is continuing and growing its stranglehold on the industry through over a decade of careful planning by the Taiwanese government. TSMC has even more room to grow as it continues to out-develop Samsung in size and density of chips, and gains an even larger market share. As the world’s technological advances continue, TSMC’s superior technology and delivery capabilities will allow them to remain a mainstay in a growing tech sector. In the case of another future pandemic (hopefully not), Taiwan is almost assured to have an effective response.

Sources

“ Taiwan.” Worldometer, 2020, www.worldometers.info/coronavirus/country/taiwan/.

Hsieh, Ying-Hen, et al. “SARS Outbreak, Taiwan, 2003.” Emerging Infectious Diseases, Centers for Disease Control and Prevention, Feb. 2004, www.ncbi.nlm.nih.gov/pmc/articles/PMC3322921/.

Chen, Kow-Tong, et al. “SARS in Taiwan: an Overview and Lessons Learned.” International Journal of Infectious Diseases, Elsevier, 25 Jan. 2005, www.sciencedirect.com/science/article/pii/S1201971204001766.

C. Jason Wang, MD. “Response to COVID-19 in Taiwan: Big Data Analytics, New Technology, and Proactive Testing.” JAMA, JAMA Network, 14 Apr. 2020, www.jamanetwork.com/journals/jama/fullarticle/2762689

Farr, Christina. “How Taiwan Beat the Coronavirus.” CNBC, CNBC, 16 July 2020, www.cnbc.com/2020/07/15/how-taiwan-beat-the-coronavirus.html.

Lee, Yimou. “Taiwan to Ban Entry for Many Foreigners in Coronavirus Fight.” U.S. News & World Report, U.S. News & World Report, 17 Mar. 2020, www.usnews.com/news/world/articles/2020-03-17/taiwan-to-ban-most-foreigners-from-entry-to-control-virus.

Wang, Cindy, and Samson Ellis. “Taiwan Achieves Record 200 Days With No Local Virus Cases.” Time, Time, 29 Oct. 2020, time.com/5905129/taiwan-coronavirus-record/.

TSMC. “About TSMC.” About TSMC - Taiwan Semiconductor Manufacturing Company Limited, www.tsmc.com/english/aboutTSMC/index.htm.

Monica Chen, Hsinchu; Jessie Shen. “TSMC 2nm GAA Process Development Ahead of Schedule.” DIGITIMES, DIGITIMES Inc., 21 Sept. 2020, www.digitimes.com/news/a20200921PD211.html.

Owen, Malcolm. “TSMC 3nm 'Risk Production' in 2021 Paves the Way to 2022 Mass Production.” AppleInsider, AppleInsider, 19 July 2020, www.appleinsider.com/articles/20/07/19/tsmc-3nm-risk-production-in-2021-paves-the-way-to-2020-mass-production.

Sun, Leo. “3 Tailwinds Are Lifting TSMC's Stock to New All-Time Highs.” The Motley Fool, The Motley Fool, 31 July 2020, www.fool.com/investing/2020/07/31/3-tailwinds-are-lifting-tsmcs-stock-to-new-all-tim.aspx.

“Apple Planning to Build New Plant in Taoyuan.” Taipei Times, 11 May 2020, www.taipeitimes.com/News/biz/archives/2020/05/12/2003736216.

“Apple Announces Mac Transition to Apple Silicon.” Apple Newsroom, 16 Oct. 2020, www.apple.com/newsroom/2020/06/apple-announces-mac-transition-to-apple-silicon/.

Sohail, Omar. “TSMC to Remain Exclusive Supplier of Apple A13 Chips for This Year, Claims Supply Chain.” Wccftech, Wccftech, 11 Feb. 2019, www.wccftech.com/tsmc-apple-a13-chips-sole-suppler-digitimes/.

Hruska, Joel. “Apple Books TSMC's Entire 5nm Production Capability.” ExtremeTech, 18 Sept. 2020, www.extremetech.com/computing/315186-apple-books-tsmcs-entire-5nm-production-capability.

Fox, Chris. “Intel's next-Generation 7nm Chips Delayed until 2022.” BBC News, BBC, 24 July 2020, www.bbc.com/news/technology-53525710.

McKellop, Mario. “Report: AMD Ramping up Chipset TSMC Production Orders: The Burn.” In, 28 Sept. 2020, www.theburnin.com/industry/amd-increasing-orders-7nm-components-tsmc-2020-09-28.

Mahaney, Ben. “Intel Is Now Ordering Chips From TSMC Following Delays.” Yahoo! News, Yahoo!, 28 July 2020, www.yahoo.com/news/intel-now-ordering-chips-tsmc-072255657.html.

“Taiwan Semiconductor Manufacturing (TSM) Stock Price, News, Quote & History.” Yahoo! Finance, Yahoo!, 23 Oct. 2020, www.finance.yahoo.com/quote/TSM?p=TSM